File:Principe etirage soufflage bouteille.svg

Size of this PNG preview of this SVG file: 590 × 389 pixels. Other resolutions: 320 × 211 pixels | 640 × 422 pixels | 1,024 × 675 pixels | 1,280 × 844 pixels | 2,560 × 1,688 pixels.

Original file (SVG file, nominally 590 × 389 pixels, file size: 129 KB)

File information

Structured data

Captions

Captions

Add a one-line explanation of what this file represents

Summary edit

| DescriptionPrincipe etirage soufflage bouteille.svg |

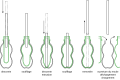

English: Principle of stretching-blow moulding of a bottle:

Français : Principe de l'étirage-soufflage d'une bouteille plastique :

|

| Date | |

| Source | Own work |

| Author | Cdang; Samuel Dupré for the advice |

This W3C-unspecified vector image was created with Inkscape .

Licensing edit

I, the copyright holder of this work, hereby publish it under the following licenses:

|

Permission is granted to copy, distribute and/or modify this document under the terms of the GNU Free Documentation License, Version 1.2 or any later version published by the Free Software Foundation; with no Invariant Sections, no Front-Cover Texts, and no Back-Cover Texts. A copy of the license is included in the section entitled GNU Free Documentation License.http://www.gnu.org/copyleft/fdl.htmlGFDLGNU Free Documentation Licensetruetrue |

This file is licensed under the Creative Commons Attribution-Share Alike 3.0 Unported, 2.5 Generic, 2.0 Generic and 1.0 Generic license.

- You are free:

- to share – to copy, distribute and transmit the work

- to remix – to adapt the work

- Under the following conditions:

- attribution – You must give appropriate credit, provide a link to the license, and indicate if changes were made. You may do so in any reasonable manner, but not in any way that suggests the licensor endorses you or your use.

- share alike – If you remix, transform, or build upon the material, you must distribute your contributions under the same or compatible license as the original.

You may select the license of your choice.

File history

Click on a date/time to view the file as it appeared at that time.

| Date/Time | Thumbnail | Dimensions | User | Comment | |

|---|---|---|---|---|---|

| current | 12:20, 9 July 2012 |  | 590 × 389 (129 KB) | Cdang (talk | contribs) | Image corrected |

| 16:16, 10 November 2010 |  | 590 × 389 (125 KB) | Cdang (talk | contribs) | {{Information |Description={{en|1=Principle of extrusion-blow moulding of a bottle: # A rough casting is placed in the mould; the blow pipe goes down. # First blowing. # The pipe goes down and pulls the plastic (extrusion). # Second blow. # The pipe goes |

You cannot overwrite this file.

File usage on Commons

The following page uses this file:

File usage on other wikis

The following other wikis use this file:

- Usage on fr.wikiversity.org

Metadata

This file contains additional information such as Exif metadata which may have been added by the digital camera, scanner, or software program used to create or digitize it. If the file has been modified from its original state, some details such as the timestamp may not fully reflect those of the original file. The timestamp is only as accurate as the clock in the camera, and it may be completely wrong.

| Short title | Principe de l'étirage-soufflage |

|---|