File:Tubular compensation pendulum.png

Size of this preview: 208 × 600 pixels. Other resolutions: 83 × 240 pixels | 166 × 480 pixels | 266 × 768 pixels | 1,161 × 3,348 pixels.

Original file (1,161 × 3,348 pixels, file size: 167 KB, MIME type: image/png)

File information

Structured data

Captions

Captions

Add a one-line explanation of what this file represents

Summary edit

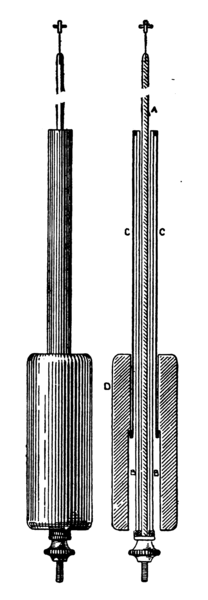

| DescriptionTubular compensation pendulum.png |

English: A tubular temperature compensated pendulum used in precision pendulum clocks, from a 1917 clock book. A major cause of inaccuracy in 18th century procision clocks was contraction and expansion of the metal pendulum rod with temperature changes. In 1726 John Harrison invented the gridiron pendulum, in which rods of two metals with different temperature coefficients, steel and zinc, compensated each other, so that the pendulum stayed the same length with temperature changes. However when expanding and contracting, the rods of the gridiron had to slide through holes in a metal frame in a series of tiny jerks, which caused the rate of the clock to change suddenly. Therefore clockmakers worked to invent a compensating pendulum using Harrison's principle which didn't have sliding friction. This tubular design was invented several times by different clockmakers, and used in a number of precision clocks during the 19th century. It consisted of a steel rod (A), inside a zinc tube (B), inside a steel tube (C), with the tubes large enough that there was space between them.. The steel rod was suspended at top from the pendulum's suspension spring. It supported the concentric zinc tube at its bottom, and the zinc tube supported the steel tube at its top. The pendulum's weight (D) was attached to the bottom of the steel tube. An increase in temperature would cause all three parts to expand in length. However because of their interconnection the expanding steel rod and tube would make the pendulum longer, while the expanding zinc tube would push it up, making the pendulum shorter. Since zinc has a greater thermal expansion than steel, by making the parts of the proper length these two effects could be made to cancel, and the greater expansion of the zinc would exactly compensate for the expansion of the steel parts which had a greater combined length, so the pendulum would stay the same length with temperature changes. The advantage of this design over Harrison's gridiron is that the rod and tubes are self-supporting, so there is no friction between parts and thus the expansion and contractions could occur smoothly, without little jumps. The pendulum's bob (weight) is attached at its center to the steel tube, so expansion of the metal bob itself with temperature will not cause the center of gravity of the pendulum to change, changing the rate. One clock which has this type pendulum is the Trinity Clock, Trinity College, Cambridge, UK Alterations to image: rotated each image slightly to compensate for slight angle at which original page was scanned, moved images closer together to save space. |

| Date | |

| Source | Retrieved June 4, 2014 from Bernard E. Jones 1917 Clock Cleaning and Repairing, Cassell and Co., New York, p. 151, fig. 96 and 97 on Google Books |

| Author | Unknown authorUnknown author |

Licensing edit

| Public domainPublic domainfalsefalse |

This media file is in the public domain in the United States. This applies to U.S. works where the copyright has expired, often because its first publication occurred prior to January 1, 1929, and if not then due to lack of notice or renewal. See this page for further explanation.

|

||

This image might not be in the public domain outside of the United States; this especially applies in the countries and areas that do not apply the rule of the shorter term for US works, such as Canada, Mainland China (not Hong Kong or Macao), Germany, Mexico, and Switzerland. The creator and year of publication are essential information and must be provided. See Wikipedia:Public domain and Wikipedia:Copyrights for more details.

|

File history

Click on a date/time to view the file as it appeared at that time.

| Date/Time | Thumbnail | Dimensions | User | Comment | |

|---|---|---|---|---|---|

| current | 07:18, 5 June 2014 | 1,161 × 3,348 (167 KB) | Chetvorno (talk | contribs) | User created page with UploadWizard |

You cannot overwrite this file.

File usage on Commons

There are no pages that use this file.

Metadata

This file contains additional information such as Exif metadata which may have been added by the digital camera, scanner, or software program used to create or digitize it. If the file has been modified from its original state, some details such as the timestamp may not fully reflect those of the original file. The timestamp is only as accurate as the clock in the camera, and it may be completely wrong.

| PNG file comment |

|

|---|---|

| Horizontal resolution | 28.35 dpc |

| Vertical resolution | 28.35 dpc |

| File change date and time | 02:49, 5 June 2014 |